up:: RDL MOC

lecture11-mechanical-design-0.pdf

What is Mechanical Design?

The design process of mechanical components and systems

(natural and artificial)

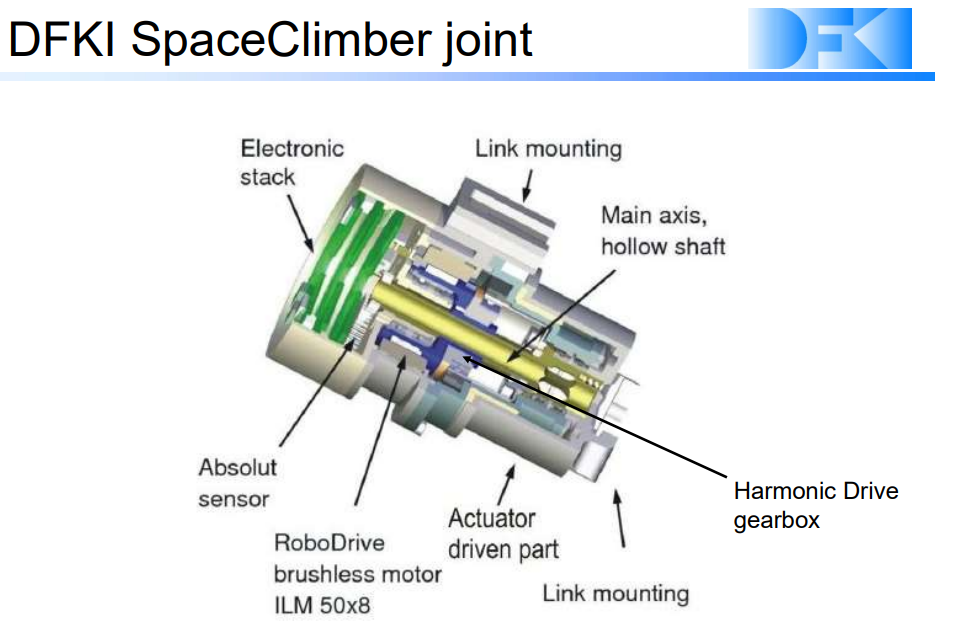

also see: Robots at the DFKI

Three steps involved in mechanical design

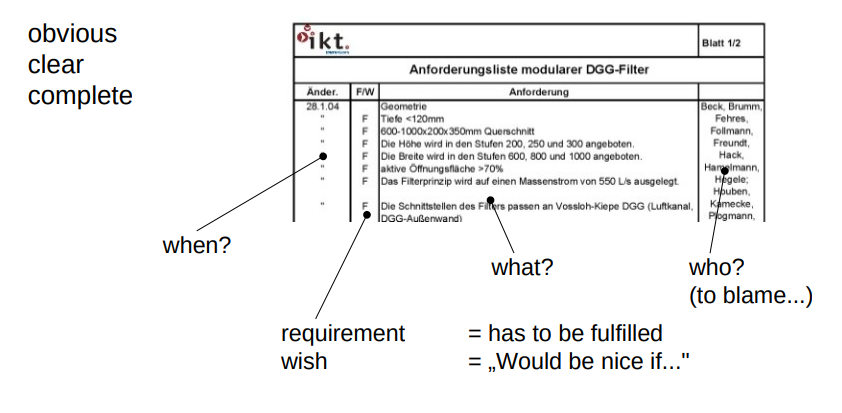

Specifications

Principles

Design

Machine Elements

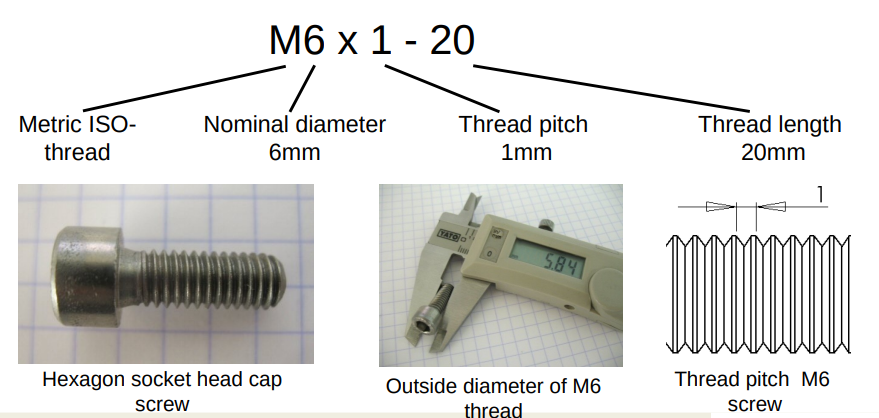

Screws

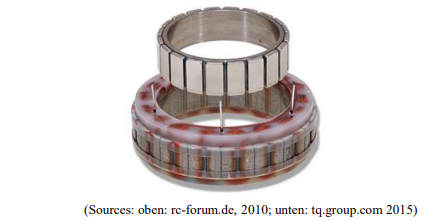

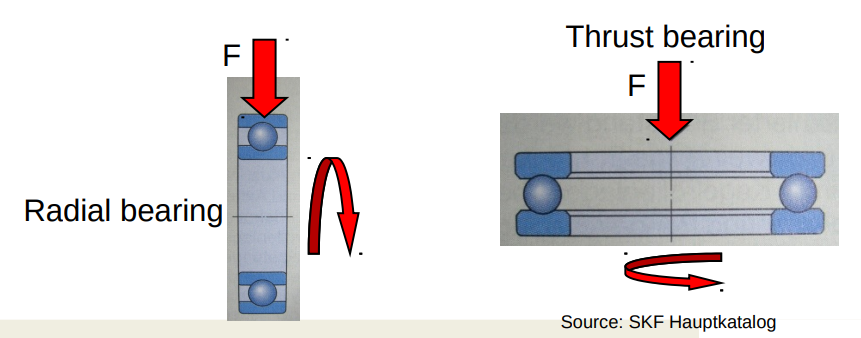

Bearings:

- Balsl for high revelotions

- Zylinder or Neelde for high Forces

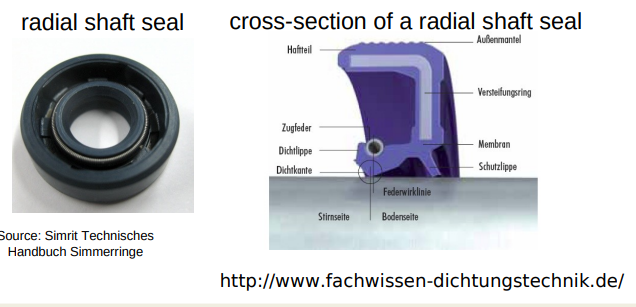

Sealings (O-Rings)

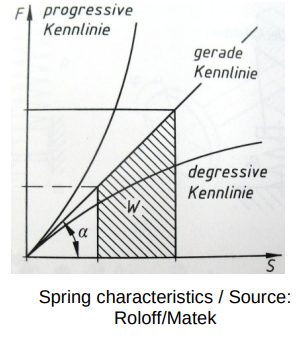

Springs

Hooks Law

Spring force [N] = spring rate [N/mm] x spring travel [mm]Link to original

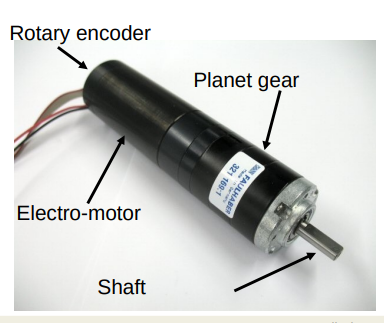

Motors

Motor

Example

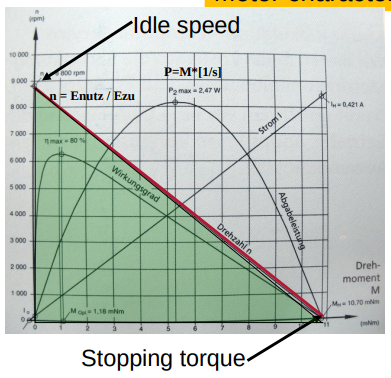

Direct current motors (DC-motors)

- Up to 98% efficiency

- Power cord or battery

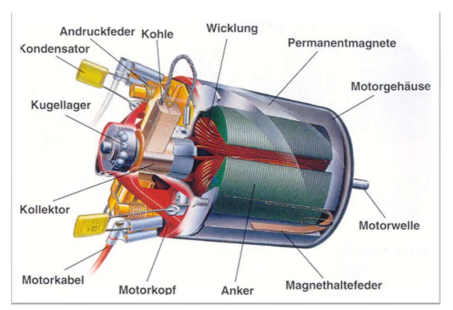

Brush motor:

- cheap

- Mature technology

- Sparking / high-frequency interferences

- Life limit – carbon brushes

Brushless motor:

- More efficient / less heat

- Less wear

- More power per weight

- Requires a controller

Stepper Motors

Revolutions will be made in an amount of steps (degree), not as a constant movement, exact positions can be achieved

Bipolar: 2 coils 4 connections (more power per motor-volume)

Unipolar: at least 5 connections, simpler control

Reluctance motor

- toothed soft iron structured rotor

- No permanent magnets

- Free magnetic flow, no magnetic field after switched off

Permanentmagnet motor

- Permanentmagnet on the shaft / Stator made of soft iron

- Moment of rest

- Lower resolution in comparison to ther reluktance motor

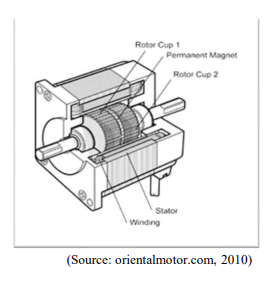

Hybridmotor

Permanentmagnet and toothed soft iron core on the shaft

Servos

- Analog servos

- Low power consumption

- Low price

- Digital servos

- Faster positioning time

- Higher resolution

- Partly programmable

- PWM-control

Common for hobby servos

Servo elektronics regulate the actor (potentiometer) against the motor position

The pulse width of the control signal regulates the target position

Various variations on pulse widths and travel ranges

Link to original

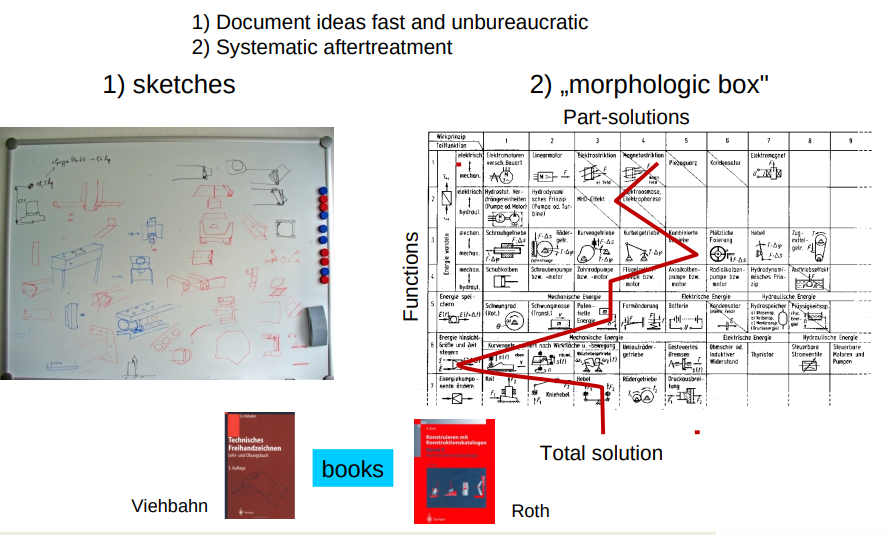

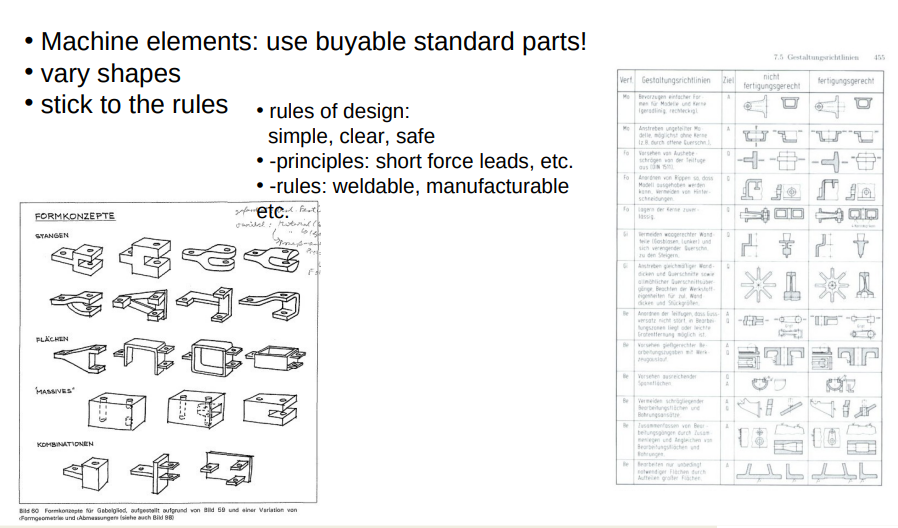

Desing

qualitative design

(norms, shapes etc.)

⇒ Knowlage about desing

quantitative design

(material, strength, stiffness, other desired parameters.)

⇒ Desinging something in a way it can’t fail

- if you have to calculate, the construction is not good.” → Observe proportions.

- Roughing calculations – survey orders of magnitude

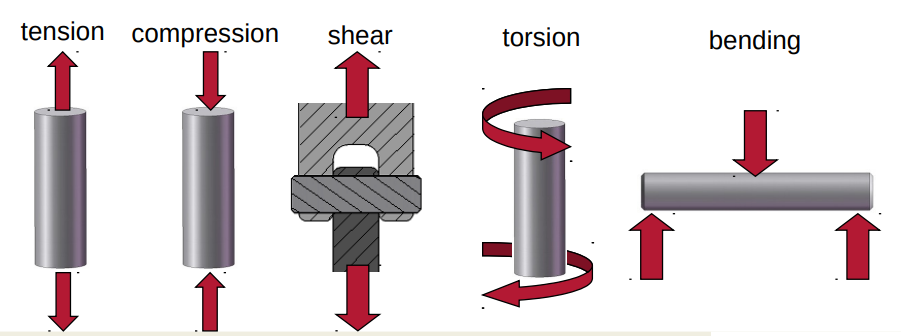

Loads

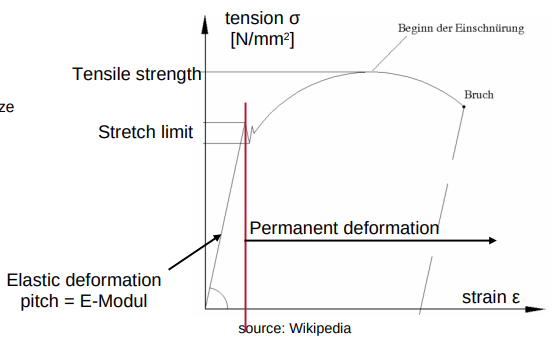

Elastic range

components behave like a „spring“

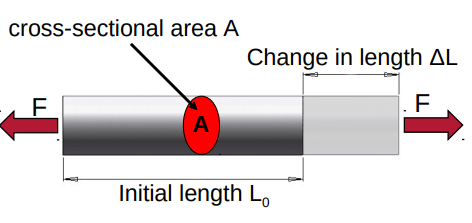

tension [N/mm2 ] = force [N] / cross-sectional area [mm2 ]

Plastic range

components deform permanently

elongation = change in length [mm] / initial length [mm]

E-modulus

The relationship between tension and elongation is called the elasticity modulus

Modulus of elasticity [N/mm2 ] = tension [N/mm2 ] / elongation

Additive and subtractive manufacturing processes

Additive

- 3D printer

- Laser sintering (SLS)

- Welding

Subtractive

-

Sheet cutting

- Laser cutting

- Plasma cutting

- Water-jet cutting

-

Milling

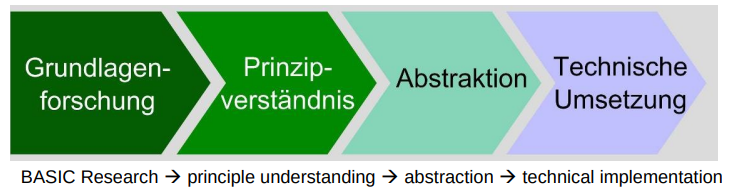

Biomimetics

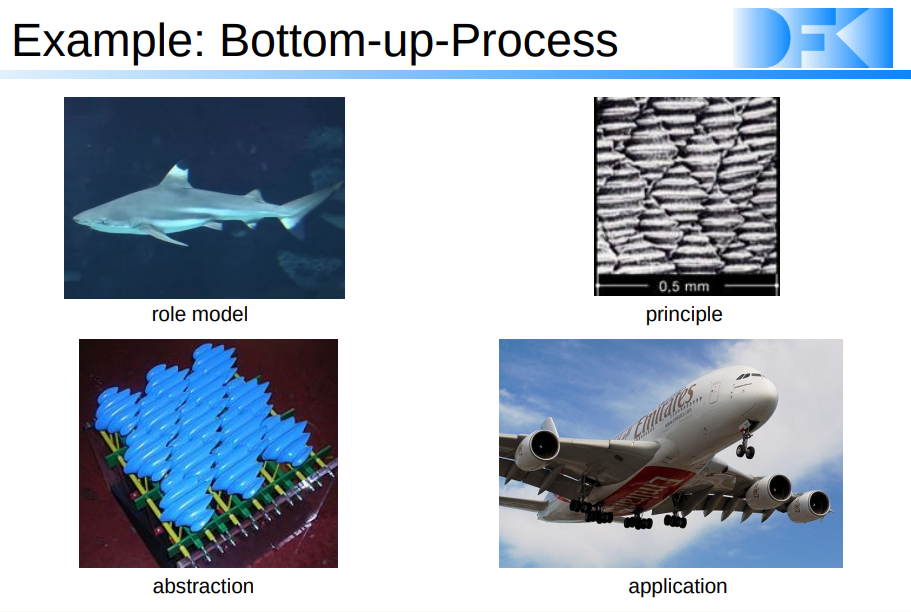

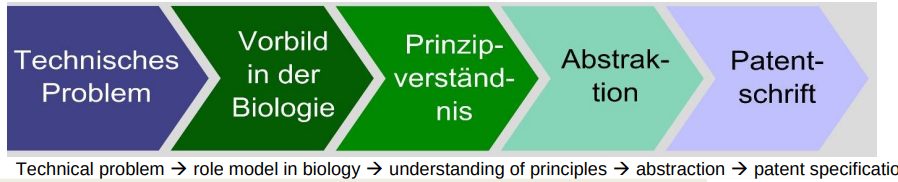

Bottom-up-Prozess

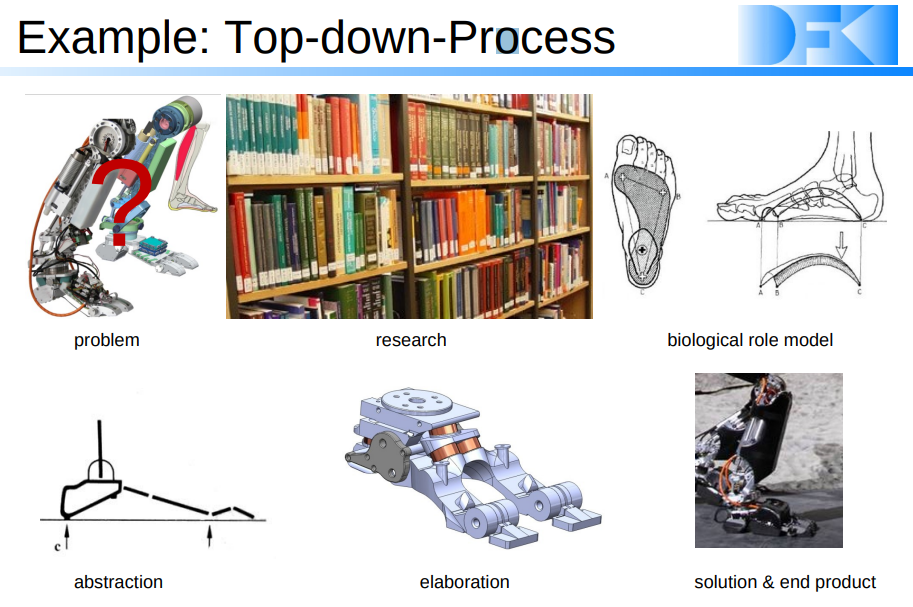

Top-down-Prozess

Link to original

Good Books

- Warum alles Kaputt geht

- Tabellenbuch Metall

next: RDL VL 12 Actuators